Pure PERFORMANCE | Absolute QUALITY

The Sling 4 Turbo was designed with the aim of creating the most practical and desirable lightweight, 4-place Experimental aircraft on the market, a niche not previously filled. The plane is basically an elongated version of its sibling, the Sling LSA, however it uses the more powerful Rotax 914 Turbo and has Gullwing doors instead of a sliding canopy. It can comfortably seat 4 people, carry baggage and still cruise effortlessly and efficiently, making it the ultimate affordable cross-country aircraft. Her flying characteristics are very similar to the smaller Sling LSA, perfectly-coordinated with highly responsive controls that are not too sensitive! The Sling 4 Turbo is the perfect aircraft for the home builder who is looking for an affordable DIY 4-place airplane. Aluminum construction is used for ease of maintenance and construction as well as its proven strength and lifetime qualities. The Sling 4 Turbo comes with a variety of customization options that the builder can explore as well as the option for a Ballistic Parachute for safety purposes. No single aircraft can fulfill the special needs of every pilot. Nevertheless, The Airplane Factory believes that the Sling 4 Turbo enjoys a set of qualities that will fulfill the needs, at the highest level, of many pilots around the globe.

The Sling 4 Turbo was designed with the aim of creating the most practical and desirable lightweight, 4-place Experimental aircraft on the market, a niche not previously filled. The plane is basically an elongated version of its sibling, the Sling LSA, however it uses the more powerful Rotax 914 Turbo and has Gullwing doors instead of a sliding canopy. It can comfortably seat 4 people, carry baggage and still cruise effortlessly and efficiently, making it the ultimate affordable cross-country aircraft. Her flying characteristics are very similar to the smaller Sling LSA, perfectly-coordinated with highly responsive controls that are not too sensitive! The Sling 4 Turbo is the perfect aircraft for the home builder who is looking for an affordable DIY 4-place airplane. Aluminum construction is used for ease of maintenance and construction as well as its proven strength and lifetime qualities. The Sling 4 Turbo comes with a variety of customization options that the builder can explore as well as the option for a Ballistic Parachute for safety purposes. No single aircraft can fulfill the special needs of every pilot. Nevertheless, The Airplane Factory believes that the Sling 4 Turbo enjoys a set of qualities that will fulfill the needs, at the highest level, of many pilots around the globe.

Available as Standard or Quickbuild Kit

Quickbuild Kit (FAA audited 51% kit) saves 400 hours

Also Available through our Build Assist Programs

Contact Us for more details

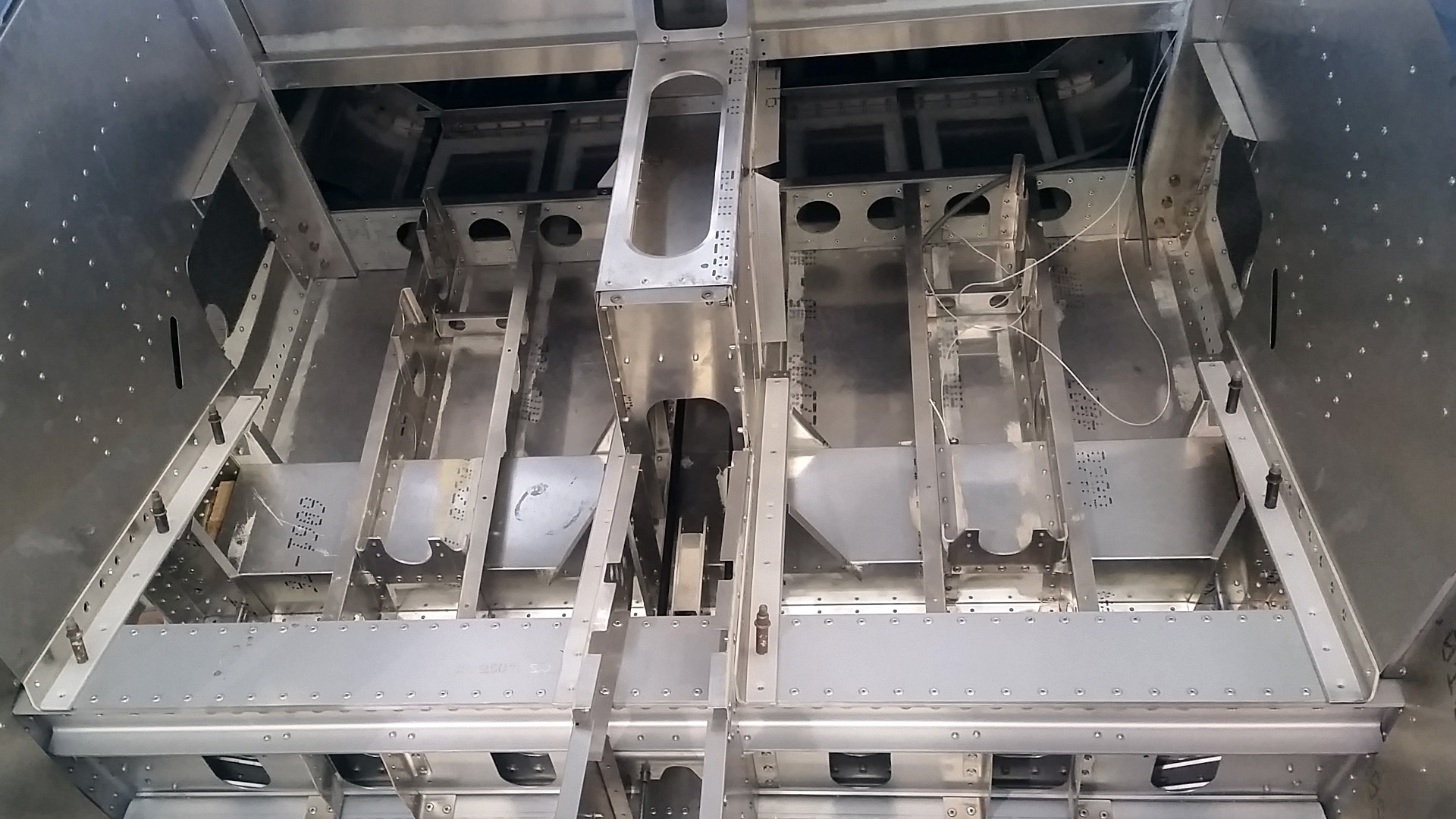

Well-Engineered, Proven Aluminum Construction

With pulled rivets for ease of assembly (solid rivets used in spar and spar box (completed at factory))

The Airplane…

Design and Construction

The Airplane Factory is proud to be the producer of high quality, high performance Light Sport and Experimental Aircraft. We take every step to ensure that each aircraft produced, whether ready-to-fly or kit version, is held to the highest of standards, above and beyond that required by ASTM or the FAA. The reason for such meticulous design and construction is because most of us here at The Airplane Factory are pilots. We know and understand the concerns of our fellow aviators and we would never build anything we did not 100% believe in or endorse. Every new design prototype is tested to its ultimate breaking points to ensure maximum reliability and durability, not too mention the extraordinary efforts The Airplane Factory goes to in order to make sure handling and stability are in the upper echelon of all airplanes on the market today. In addition, each kit we produce is inspected and assured to be top quality before being shipped to the buyer. The Airplane Factory founders feel that the Sling airplanes and kits are the best on the market and believe that you will soon agree!

The design was conceived in 2006 as a result of Mike Blyth’s desire for a Light Sport Aircraft (LSA) that had better performance and handling characteristics than anything on the market. This vision would be an airplane capable of acting as either an exciting pleasure craft or a forgiving trainer. Mike decided to go with a stressed skin, riveted design for its proven technology, durability, and ease of construction. He also wanted to make an all-metal, low wing airplane that would have excellent visibility, sporty handling, and a sleek and sexy exterior.

The aluminum he chose was 6061 Aluminum Alloy. To be more specific, 6061-T6 Aluminum, a tempered grade that has been heat-treated and aged to add a significant strength element. The Sling uses all traditional AN Hardware in its construction, meaning it lives up to the US Air Force/Navy Standards. Solid rivets are used on the main spars, which are standard aviation type spars with our own unique design for added strength, and pull rivets for the rest of the structure, making construction a bit easier while maintaining structural integrity. The Airplane Factory uses high quality rivets manufactured in Germany that are well known throughout the aircraft manufacturing industry. Composites are also used throughout the airplane where appropriate, for example, cowling, fairings at the wing roots and the intersection between the vertical stabilizer and the fuselage, wheel pants, as well as the instrument panel and canopy structure. For reduced weight but added strength, the landing gear is also composite construction which can take a heavy amount of stress regularly without issues.

The standard assembly process for each Sling begins with the different aircraft subsections being assembled. After the Empennage, Wings, and Fuselage are ready they are sent off to receive their Primer and Epoxy painting. Concurrently, the engine, electronics and canopy are fitted. When the parts come back from painting the wings and empennage are bolted to the fuselage and tested. Lastly, the fairings are put in place and the aircraft is ready for testing.

Each part of the aircraft manufacturing process has a full set of quality control procedures that The Airplane Factory directors personally oversee. Each part part is carefully inspected and all metal is punched precisely by our CNC machines. The quality assurance managers then inspect the entirety of the shipment before sending out to the buyer.

Sling 4 Turbo Videos

Handling

The Sling 4 Turbo’s flying characteristics make for a perfectly coordinated, highly responsive control setup. This gives her the distinct qualities of a fighter jet aircraft, while not being overly sensitive. Comfortable for the whole family. The Sling is a Pilot’s Airplane. You fly it for the love of it.

Looks

Ramp appeal. You want your airplane to look as good as it flies. The Sling 4 Turbo has bold, sexy, aggressive lines. You’ll feel proud stepping out of it.

Glass Cockpit

The Sling 4 Turbo’s avionics options make for a very unique, state-of-the-art flying experience, at a fraction of the cost of our certified competitors. Full integrated EFIS with autopilot, radio and transponder with 2020-compliant ADS-B is available with live weather and traffic alerts in the cockpit. No more flying blind.

Gullwing Doors

The Sling 4 Turbo’s Gullwing doors make for easy ingress and egress for all 4 occupants. The wide cockpit, excellent all around view and substantial luggage capacity make the Sling 4 Turbo a very comfortable, yet versatile aircraft.

Spacious Cabin for 4

The Sling 4 Turbo has a spacious cabin for 4 people. With ample knee-room in the back seats, there is a feeling of roominess in the cabin. The Sling 4 Turbo has as much cabin space as many much-larger aircraft.

Safety

The sturdy construction of the Sling 4 Turbo make it an aircraft able to go the distance, reliably. The incorporation, by design, of a ballistic parachute, makes the Sling an exceptionally safe aircraft to fly. The use of high quality components throughout gives you, the owner, the peace of mind that you deserve, when making this kind of investment.

Turbo Performance

The Sling 4 Turbo’s turbo-normalized Rotax 914 engine, combined with the Airmaster Electric Constant Speed Prop, provides outstanding performance. At max gross weight, with 4 adults onboard and full fuel, the Sling 4 Turbo climbs at 900 fpm. It maintains a solid indicated airspeed up to altitude resulting in cruise performance of 130 KTAS+

900 fpm climb

130 KTAS+ cruise above 9,500′

Economy

With an operating cost of around $50/hr and burning just 6GPH of car gas, the Sling 4 Turbo is the efficient, economical cruiser of the modern age.

Detailed, Industry-Leading Assembly Manual with CAD Exploded Diagrams

Specifications

| Sling 4 Turbo Performance and Specifications | |

|---|---|

| Cruise Speed: | 130+ ktas |

| Fuel Burn: | 6 gph |

| Rate of Climb: | 900 fpm |

| Max Range: | 900 nm |

| Fuel Capacity: | 46 gals |

| Max Gross: | 2,024 lbs |

| Empty Weight: | 1,012 lbs |

| Useful Load: | 1,012 lbs |

| Wing Span: | 32.7’ |

| Cockpit Width: | 44” |

| Engine Type: | Rotax 914 UL |

| Power: | Turbo Charged 115 HP |

Quickbuild Kit Option

Get it done quick (51% kit)